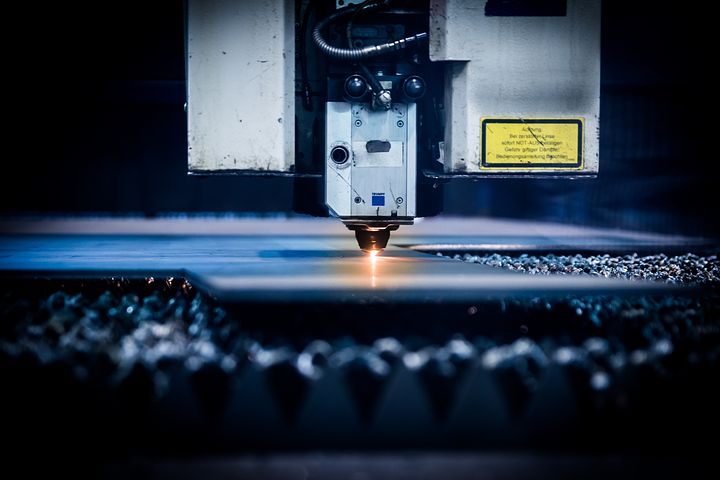

Local practitioners who have the chance to invest in a laser cutter will realise that the purchase provides them with a world of opportunities.

From making small intricate products to running repairs on larger materials, these machines are becoming more commonplace for people who need expert machinery to reach their objectives.

Rather than continuing with outdated cutting utilities, this offers an opportunity for members to engage these brands and use them for a range of purposes.

We will discuss the leading features of these models to demonstrate why they are a great purchase option.

User-Friendly Formatting

Local developers who want to utilise these machines will find that they have a system in place that is simple and user-friendly. While extensive technology like this used to be exclusive to niche industries, this is now an asset that is incorporated with helpful software programming adaptable for Apple and Android outlets. With the aid of a comprehensive dashboard, users can drag and drop features, save their work on cloud-based computing systems and ensure suitability for their projects irrespective of their circumstances.

Versatile Material Engagement

Whether it is direct cutting or engraving, the inclusion of a laser cutter at a workstation will offer people the chance to introduce a myriad of materials. This is helpful for designers, artists, builders, technicians and others the opportunity to shift their programming according to their unique needs. From hardwood and softwood to glass, ceramic, plastic, cardboard, stainless steel, marble, tile, aluminium and cork, very few surfaces will be off limits.

Safety Assurances

Participants who are working on materials and manipulating them for creation, repairs or maintenance will need to know that they have a safe asset that doesn’t place them in harm’s way. A defining feature of these brands is that there is zero contact required. For the sake of avoiding contamination and facing the risk of injury or casualties, at no time will the user need to have their hands directed around the cutter while it is in operation.

Process Speed

Once individuals place the materials in position, their laser cutter will fast track the procedure. This is a format that works to high levels of efficiency, cutting down a program which would otherwise take hours or days to complete. It is ideal for clients who have a lot of projects on their plate, or have high demands from their customers and stakeholders, ensuring they achieve quality outcomes on a shorter schedule.

Supplier Support

The reason why these cutter designs are so valued by operators will be due to the expertise and guidance offered by suppliers. There are cases when people are not up to speed with how they work and how they should be utilised for their specific needs. Rather than make mistakes and assumptions along the journey, whether it is in professional spaces or for personal use, this will be a chance to watch tutorial videos, acquire instructions and contact representatives who walk users through the process one step at a time.

Expert Accuracy

With the demands placed on professionals and amateurs alike with their development work, they want to know that the investment will pay off. With enough evidence to review their performance, the modern laser cutter brand will deliver a cut that is listed with a 0.0005-inch margin of error. It will be the kind of precision that specialist manufacturers achieve and there will be no clear difference between practitioners at home and the big brands.